As the world continues to deepen its knowledge and transform its traditional workflows to CAD, fashion designers and organizations are hesitant to take on the task. The fashion industry is continuously under pressure to stay on trend and keep up with the constant flow of building new collections; however, traditional business models are too reliant on manual steps, more prone to errors, too slow in getting their products to market and inefficient.

Technology profoundly impacts how we communicate, engage, teach, work, and learn. As the apparel industry is now moving into the digital era, apparel organizations need to transform their workflows to meet the challenge and capture the opportunity that the world of digital brings .

So, if you’re still debating the benefits of digital transformation in the apparel industry, here are four signs that you should go digital:

1. You’re Over-Producing

Over-production is one of the most significant challenges faced by the apparel industry today, and the biggest question is, where do all the unwanted clothes go?

Traditionally, apparel organizations have overproduced garments for various reasons. A few of them are a shift in the consumer mindset, inaccurate market predictions, and skepticism of suppliers’ ability to deliver clothing without delay. While some of the unwanted garments may be sold at a discounted price, remarketed, or donated, most of the remaining garments are buried or burnt inside landfills, contributing to the prevalent environmental crisis within the apparel industry.

This is where 3D garment design comes in to combat the ongoing issue of overproduction. With advanced technology, apparel organizations can create garments on-demand as soon as they are ordered, which helps organizations boost their efficiency and minimize unnecessary costs associated with overproduction.

2. You’re Depending too much on Physical samples

When it comes to producing physical samples, there is no denying that the sampling process is essential for validating designs before they are produced in bulk.

However, time is a valuable commodity, and the traditional sampling process can potentially add up to 4-6 weeks on your apparel calendar. Once the samples have been analyzed, approved, or denied, they wind up in landfills, contributing again to the ongoing waste crisis.

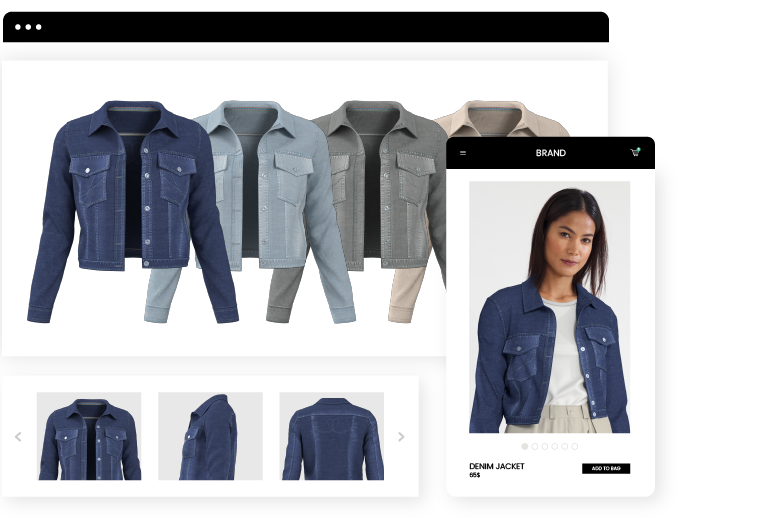

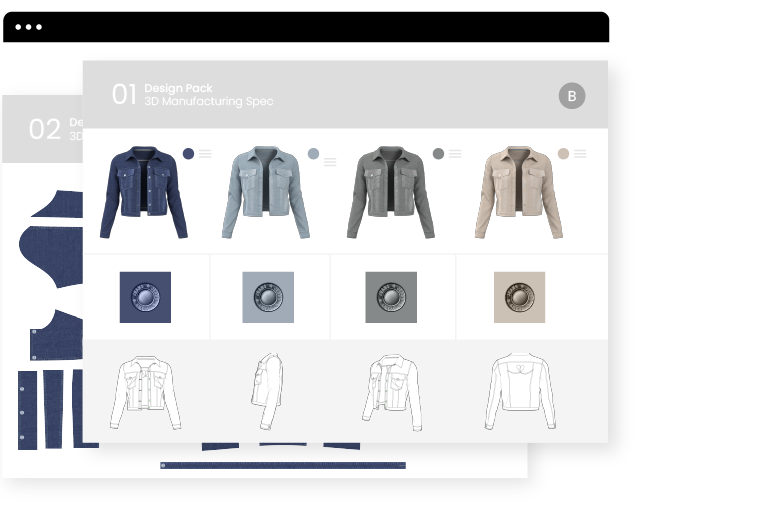

As fashion companies adopt 3D apparel design software to their workflows, they can create endless iterations of a true-to-life digital sample that can be shared instantly across the organization. Therefore, by adopting 3D CAD, fashion designers and organizations can better streamline their process and make confident decisions regarding the fit and styling of a digital twin of the physical garment.

3. You’re Spending Too Much Time Getting Your Products to Market

Generally, the timeline of apparel organizations getting their products to market could take up to 52 weeks, and this includes the back-and-forth communication and decision-making between stakeholders, the hours spent transporting the samples as well as the fit and style validation of the garment, making it harder and more stressful for brands to stay on trend for each season.

However, when the pandemic hit, apparel organizations could not survive without digitally transforming their workflows, as the physical aspect of designing a collection was almost impossible to maintain.

For that reason, many apparel organizations have started to reinvent their business models and adopt digital solutions to accelerate their product’s time to market, bridge the gap between stakeholder communications and minimize all the wasted time and costs while upholding the quality of the collection.

4. You’re Guessing When It Comes to Size and Fit

When a garment does not fit or feel right on the consumer’s body, the consumer will return the item, leaving them dissatisfied and increasing cost and waste for the retailer.

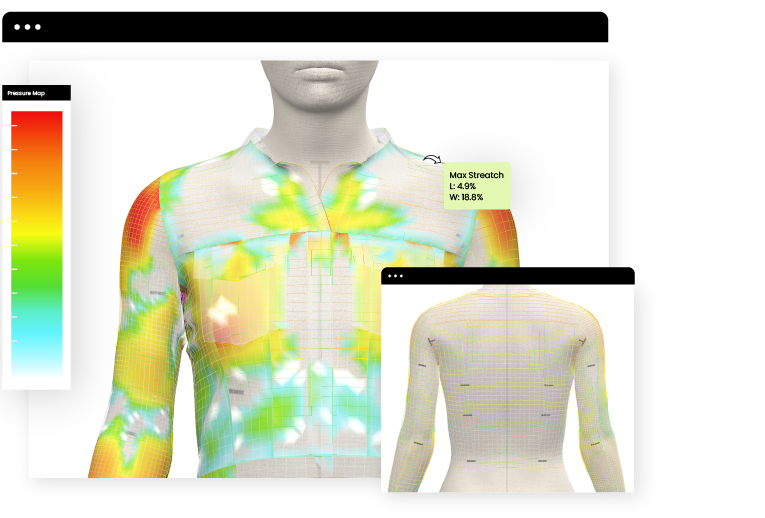

The goal of apparel organizations is to get the collection to the store and for the consumer to feel good and proud about what they are wearing, resulting in customer loyalty. Therefore, apparel organizations must get the size and fit right the first time and the best way to do that is to go digital.

A 3D apparel design workflow enables apparel organizations to validate and visualize the overall look and feel, from the cut and style down to the fabric and drape of the garment, all at first glance.

While the apparel industry has upheld its reputation as boundary-pushing, it is now time for them to shift from their traditional workflows and take on the world of 3D. With 3D CAD, fashion designers and apparel organizations will be able to encapsulate their vision perfectly while reducing costs, time, and a lot of waste.