Company Overview

Established in 1976, Halti is one of Finland’s leading outdoor sportswear brands. Initially gearing its collections toward camping and hiking, the brand has significantly grown and diversified over the years, now producing an extensive range of innovative apparel for all different types of sporting activities for all seasons. Halti has always been committed to sustainability, taking great responsibility for its social and environmental impact.

The Need for Change

Being a company that produces such a wide variety of durable, high-quality garments each season, Halti constantly looks for new and innovative ways to better its product lifecycle and make its process more efficient, from both an environmental and business perspective. Over the past few years, the product development team became increasingly determined to speed up the go-to-market time and reduce the number of sample iterations throughout the approval process. Therefore, the team searched for a solution that would enable the company to make its vision a reality.

After researching different options, the company began to re-think its traditional strategies and look into the concept of 3D as a way to build a more streamlined and sustainable design cycle, collaborating with Browzwear in 2017 to achieve its goals. “Sustainability is an important value for Halti. Three years ago, we decided that it is pointless to fly clothing proto pieces back and forth around the world when design and testing can now also be carried out with 3D technology” says Laura Roman, Head of Operations at Halti.

Incorporating 3D to the Design Workflow

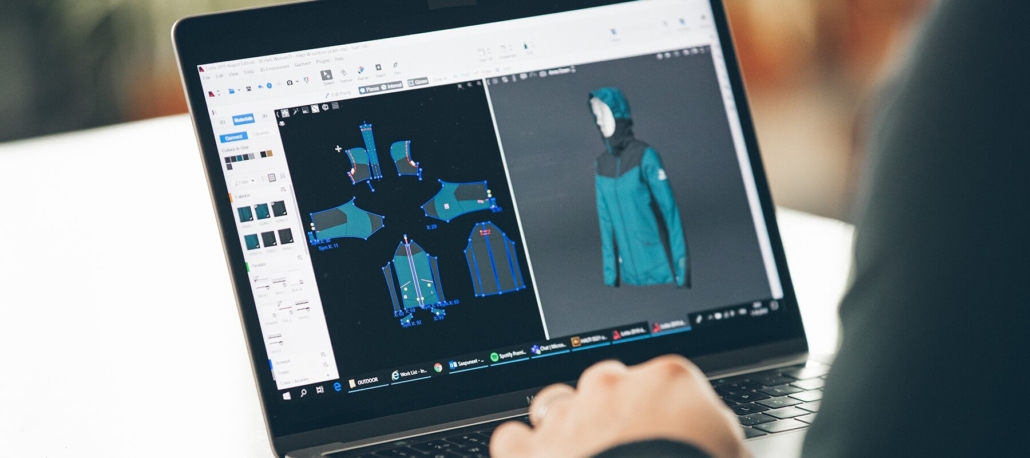

Halti began its digital transformation journey by incorporating 3D into their design workflows for base layers and t-shirts. By having the ability to leverage true-to-life digital garments, the design teams could effectively shift much of their day-to-day manual tasks to digital, thus creating a faster and more efficient sampling strategy. Additionally, the number of sample iterations needed throughout the approval process was drastically reduced, saving both time and natural resource consumption.

It wasn’t long before the initial design phase was carried out entirely digitally. By establishing a digital design workflow, the design team experiences far more fluidity throughout the process, reducing the lengthy wait time between approval rounds. Laura notes that “by being able to check the pattern on the avatar first, the approval process is reduced by one to two rounds at least”. Aside from the practical aspects, the designers at Halti could freely experiment with different concepts and express their creativity without limitations. “When working with VStitcher, designers have the ability to take styles from previous seasons and modify them for upcoming collections,” says Laura.

The Impact of 3D

Since the implementation of 3D design workflows, Halti’s product development team now utilizes virtual garments when presenting styles to stakeholders as well as for frequent review meetings. By doing so, not only are physical samples are cut but as decisions can be made with accuracy and speed, new products can be launched at a faster pace. The company also enjoys more fluid collaboration between departments, as any design adjustments can be communicated over the digital twin of the physical garment and modified instantly. When it comes to sustainability, the digitization of the design workflow has significantly decreased the number of physical samples Therefore, the brand can cut back on natural resources, lower its emissions, and reduce textile waste.“From SS20 to SS21 we have reduced the number of salesman samples by 50% – this means 50% fewer emissions,” says Laura.

Gearing up for a Digital Future at Halti

The success of digital tools within Halti’s design departments has given the brand the confidence to further embed them into its workflows as it continues to make a positive impact. Although the expansion of 3D within the company is currently a work in progress, the product development team is eager to scale up, and soon be able to utilize it all the way through to eCommerce. “We hope that in the near future, our sales team will be able to showcase the upcoming collections to customers using 3D garments, eliminating the need to manufacture and fly model pieces for resale,” says Laura.

Benefits of 3D for Halti