Accelerate Workflows,

from Sketch to Store.

Empowering over 1,000 fashion and apparel companies as they navigate their path toward digital transformation.

TRUSTED BY THE WORLD'S BIGGEST BRANDS

Connected

by Creation

Breaking down barriers between digital and physical,

the virtual and the actual.

Create

Leverage a true-to-life digital prototype to produce infinite variations of your designs and instantly share them across your organization.

Validate

Efficiently execute workflows and make well-informed decisions by conducting precise fit and style validation using a digital twin of the physical garment.

Communicate

Maximize customer satisfaction and reduce returns by exhibiting collections digitally and obtaining customer feedback prior to production.

Sell

Present apparel collections through engaging 3D catalogs and virtual showrooms, while animating 3D salesman samples to capture all details and movements.

Produce

Generate a comprehensive production-ready tech pack that accounts for each physical and visual property of the garment.

Fewer Samples,

Faster Decisions

Virtual prototypes accurately represent real-life products, resulting in streamlined sampling and production processes. As a result, ideas are brought to the market quicker, while minimizing costs and waste at every stage of the process.

Adaptable Solutions Catered to Your Business Needs

As the fashion industry continues to undergo a digital transformation, it is not just the garments that are getting a new look. As workflows become digital, the way in which teams work together changes as well.

CUSTOMERS STORIES

Hear From

Our Customers

Leading fashion brands and manufacturers around the world use Browzwear's 3D fashion design software to accelerate product development.

-

"By going completely digital with 3D technology, we witnessed a remarkable 70% drop in our initial investment, enabling a more efficient design workflow."Michaela Jauk

Watch full story

3D Project Leader, Odlo -

"Typically, the old way of doing things would take us three to four months, but using 3D technology before issuing samples cuts this time in half to about 2 months."Mark Donelly

Watch full story

Co-Founder & COO, Paladin -

“We found that we have reduced sampling by 50% by introducing 3D, which is a huge cost saving and time saving."Jacqui Lowe

Watch full story

Global Technical Officer, KOOKAI -

"The reduction of samples varies from 50 to 100%. In some cases, especially with less complex product groups, production can confidently move forward without requiring any physical samples."Torben Böhm

Watch full story

Manager of Technical Product Development & Digital Innovation, Bonprix

Gain Back

Your Time

With Browzwear's 3D fashion design software, you can leave the days of endless iterations behind and reach your market faster with the best selling product. The apparel digital twin gives you the power to visualize and validate every detail so that the first physical sample is the only sample.

Our Products

Stylezone enables you to build, review, align, and share seasonal collections anytime and anywhere.

Learn about Stylezone

VStitcher is the fashion industry’s leading 3D apparel design and development software.

Learn about VStitcher

For a workflow based on validated blocks, use Lotta to create new styles with an endless variety of design.

Learn about Lotta

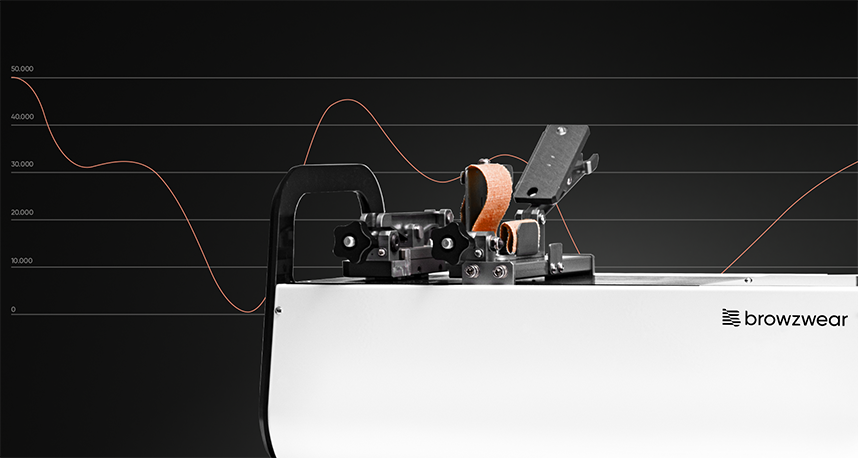

Fabric Analyzer is a system that accurately determines all of the physical properties of any fabric.

Learn about FAB

Open Platform enables technology providers to connect to Browzwear products.

Learn about Open Platform

Partners and Guilds

Simplify workflows, amplify your solution.

Trapdoor Creative

BeProduct

ByondXR

Afsha Iragorri

New York

We Enable Apparel Companies

to Digitally Transform Their Business.

.png)