Why Vendor-Brand Collaboration Is Key to Fashion Supply Chain Agility

Discover how vendor-brand collaboration and digital workflows drive fashion supply chain agility, reduce risk, and speed up time to market.

September 13, 2020

The Redress Design Awards Asia, one of the world’s largest sustainable fashion design competitions, brings together talented, aspiring fashion designers from across the globe to showcase original, zero-waste apparel collections and compete for valuable prizes. However, as the fashion world was recently faced with a new set of challenges, Redress celebrated its 10th anniversary a little differently than planned, carrying out the competition entirely virtually.

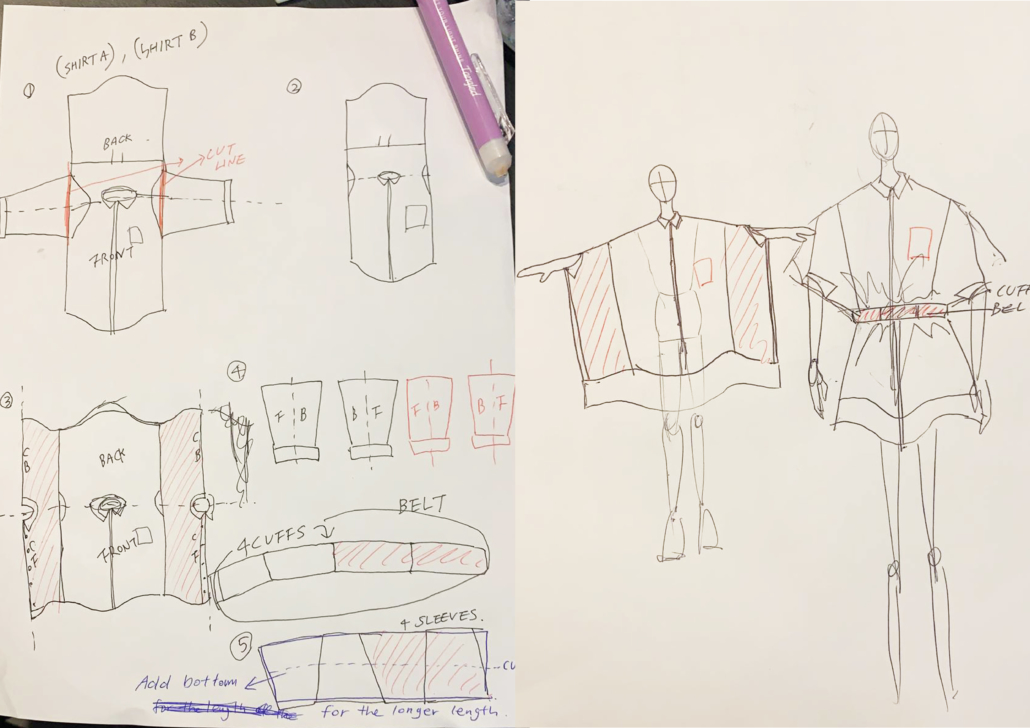

As we continue to live in a post-COVID environment, a vast number of manufacturers experienced increased quantities of deadstock due to last-minute cancellations and collection delays. In some cases, production came to a drastic halt in the midst of the process, leading to large-scale disruption across the supply chain through to retailers. Therefore, to promote the importance of embracing digital tools in light of the pandemic and the opportunities that they present, this year, the 10 Redress Awards finalists took on the Digital Up-cycling Challenge . For this competition, the finalists were divided into teams of three and given the unique task of virtually transforming deadstock samples provided by innovative manufacturer TAL Apparel Group , and bringing them back into the production line using our 3D apparel design software, VStitcher , in just 48 hours.

Ten days before the competition, the teams set out on a mission to learn how to navigate VStitcher through Browzwear’s latest e-learning platform, Browzwear University . Throughout the process, they were also given access to the Browzwear community forum for some additional tips and tricks and attended a breakout session with our 3D product specialist, Neel Brosh. This enabled them to gain a general understanding of the software and all of the foundational tools needed for 3D garment creation.

Ten days before the competition, the teams set out on a mission to learn how to navigate VStitcher through Browzwear’s latest e-learning platform, Browzwear University . Throughout the process, they were also given access to the Browzwear community forum for some additional tips and tricks and attended a breakout session with our 3D product specialist, Neel Brosh. This enabled them to gain a general understanding of the software and all of the foundational tools needed for 3D garment creation.

Once the teams had their up-cycled 3D garments rendered and ready to go, they were then asked to present the final pieces to a panel of judges including Browzwear’s Co-founder and CEO Sharon Lim and TAL Group’s CEO, Roger Lee. During the presentations, the teams also provided an estimation of the waste use efficiency, production time, and an indication of the associated costs throughout the process. It was incredible to see just how quickly each of the teams grasped the software when taking a look at the results, and we had the pleasure of rewarding the winning team with a 1-year VStitcher license to enable them to further develop their 3D design skills as they pursue their careers in the field of innovative and sustainable fashion.

Once the teams had their up-cycled 3D garments rendered and ready to go, they were then asked to present the final pieces to a panel of judges including Browzwear’s Co-founder and CEO Sharon Lim and TAL Group’s CEO, Roger Lee. During the presentations, the teams also provided an estimation of the waste use efficiency, production time, and an indication of the associated costs throughout the process. It was incredible to see just how quickly each of the teams grasped the software when taking a look at the results, and we had the pleasure of rewarding the winning team with a 1-year VStitcher license to enable them to further develop their 3D design skills as they pursue their careers in the field of innovative and sustainable fashion.

Congratulations to the winners: Grace Lant, Ruth Weerasinghe, Inhwa Jin, and Juliana Garcia Bello.

September 15th, 2020

Discover how vendor-brand collaboration and digital workflows drive fashion supply chain agility, reduce risk, and speed up time to market.

Discover how Browzwear’s colorway and graphic automation help fashion teams save hours on material updates, reduce errors, and speed up...

Discover how Browzwear’s colorway and graphic automation help fashion teams save hours on material updates, reduce errors, and speed up...