Reviving the 90's: Exploring the Creative Journey of the IACDE Winners

Creativity and innovation defined the 23/24 IACDE Summit, ‘Back to the 90s,’ honoring an iconic fashion decade.

September 19, 2019

Written by Sharon Lim, Browzwear CEO

This post was originally published on WhichPLM

The political climate and the economic instability that the world has been experiencing in recent years is resulting in growing volatility, uncertainty, complexity and ambiguity (VUCA). Political posturing, trade protectionism, and retaliatory trade measures, intensifying natural disasters – some of which are at least partly attributable to climate change – are exacerbating an already difficult set of circumstances. These changes are affecting the business world in ways we have not seen before.

The fashion industry, which in the last 10 years has been characterized by a high level of unpredictability even in the best of days, is in a particularly precarious position. Social media and e-commerce have exposed consumers to trends / styles / news more rapidly and created more demand for wider choices & personal value shopping. These have made it challenging for retailers & brands to predict consumer preferences.

These can be influenced by any number of factors, including some as capricious as celebrities’ flavor of the month. Therefore, even the latest fashion can often have extremely short lifecycle. This makes forecasting demand with any degree of accuracy for a given period, let alone for a very short one, almost impossible.

Consequently, commercial success or failure in this industry is strongly linked to organizations’ level of agility which means it’s responsiveness and flexibility. Identifying changing trends, designing apparel that is in demand and getting it to the market before preferences change, as well as being able to deal with fluctuations in demand by scaling up and down promptly, are crucial to competitiveness and to success.

Agility increases sales. It’s that simple. While in the past the fashion industry operated by seasons, today new styles are continuously being launched. Agility affects organizations’ financial sustainability. Quick response improves the likelihood of successfully countering the unpredictability of a rapidly evolving marketplace.

An organization’s agility involves several parameters: its ability to respond quickly, either reactively or proactively, to detect changes; to exploit to the fullest the range of competencies that support efficient operation; to make the most of its available resources in a flexible manner; and to shorten lead times.

Diverse factors determine the level of agility and responsiveness. Some of the main ones are:

The effects of VUCA are causing organizations to rethink the way they operate with SCM partners they rely on, as they seek to minimize the risks of uncertainty and unpredictability.

Traditional outsourcing to remotely located SCMP is a cause for a longer lead time which the industry can ill-afford with today’s fast-changing environment. The fragmented workflow between design, development, manufacturing, and logistics all adds to the challenges especially when it is common that each of the roles & responsibilities is also located in different countries and managing the complexities of language, culture, rules & regulation often increases the volatility.

Furthermore, some of these countries are now more prone to suffer devastating natural disasters such as sudden flooding, which impacts on their vendors’ ability to reliably deliver their products on time. And now, the current trade tensions where tariffs that will impact the bottom line are very worrisome.

Relocate SCMP could likely also cause a problem as it will take time to source, build up new partnerships in other regions. While this delay may be temporary, it’s likely to negatively impact financial sustainability and also the ability to supply on time.

High-level process alignment, both within the organization and externally with partners, is also crucial to maintaining a responsive supply chain. And the more entities involved in the product lifecycle – from concept, through design and manufacture, to physical garments available on store shelves or in online stores – the greater the importance of smooth connectivity, as any delay in the transfer from one link of the chain to another slows down the process as a whole, and compounds the problem.

Such uncertainty means that some larger organizations are now implementing more flexible arrangements and working with a wider range of providers, often preferring small manufacturers that specialize in specific parts of the production process. For example, a certain retailer outsources labor-intensive work such as cutting & sewing, and with the help of the latest laser technology can carry out customized wash at an economic scale.

Such organizations have further optimized by providing support (logistical and technology, new workflow) to their SCMP to ensure continuous quality even with demands for tighter deadlines.

Optimizing inventory management also contributes to agility and to an organization’s overall performance. Being able to move inventory quickly through the supply chain is a critical success factor, as it prevents the need for large discounts when demand changes from forecast and avoids unwanted inventory pile up. It is no secret that a leaner & better inventory turn around often translate into a better margin for the organization.

I do believe that the industry can gradually transform from the current “Make to sell” to a “Sell and then make” model. And we have witnessed new brands and business models which support this.

Eliminating unnecessary inventory is also good practice from a sustainability viewpoint. This is one mission that drives the vision of BW to digitally transform the industry…. To eliminate the need for a physical until demand is validated. The fashion industry is the 2 nd highest polluter of the earth and as much as possible, let’s not make until an organization knows it has been sold.

Technological advances have made their way into the fashion industry, where their favorable impact is felt and appreciated. Without a well-planned, agile & connected product lifecycle, organizations have little chance of remaining sustainable. Harnessing technology is the answer.

Some technological solutions were developed for businesses in general, to help complete tasks efficiently and effectively and to eliminate errors, and can be customized to meet an industry’s or an organization’s specific needs. These include, for example, ERP (Enterprise Resource Planning) software, asset management software and inventory optimization software. Other technological solutions were developed specifically for the fashion industry, with its unique requirements in mind.

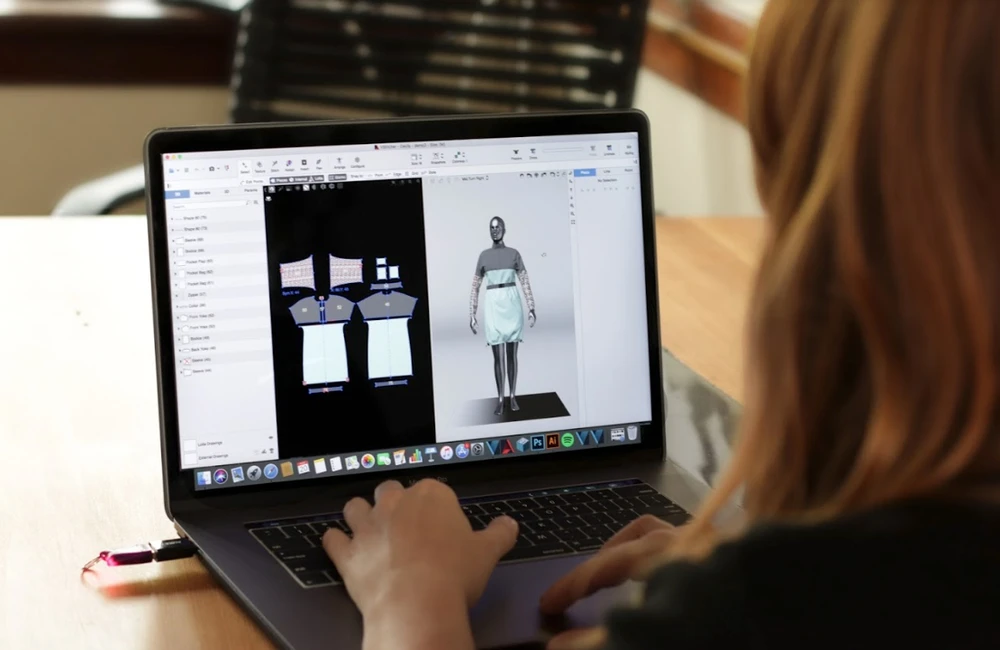

Fashion design software that creates one continuous workflow, advanced 3D design, development, & viewing capabilities, along with other features that supports automation, efficient transfer of information for manufacturing, allows expediting not only garment design, but also shortening lead time to bring the design to life. Thanks to these technologies, the need to order samples from vendors in distant countries, often repetitiously, has become obsolete. And importantly, as earlier mentioned, the avoidance of negative environmental effects will lead to sustainability which will positively impact the fashion industry’s reputation.

The emergence of trend prediction engines, consumer analytics platforms that give organizations new insights on consumers’ demands are powerful to support an organization as it plans it’s designed.

New digital materials platforms that support the fashion industry with digital libraries and costings help organizations to connect designers to available inventory and help to optimize the agility of an organization. For example, the integration of cost in such platforms to designers tools can simplify and expedite the creation & decision making of a design.

Process alignment can now be enhanced with the use of new generation web-based software that is connecting the different entities involved in the product lifecycle, regardless of their location on the globe. The flow of information and coordination, to achieve a high level of efficiency and improve responsiveness, are now much more straightforward than before, through flexible and powerful open platform ecosystems.

Yet it is also important to note that agility in the fashion industry requires changes, first in mindsets, organizational structures and practices, and oftentimes – radical ones. This is essential at a time when the industry must transform itself from being forecast-driven to being demand-driven, and adapt its response time to rapidly changing customer preferences in order to survive.

To move away from practices that were suitable for mass production and adopt new ones that are more market sensitive and economically agile, organizations must exploit the benefits of new tools, improve systems integration and networking, and align their processes to meet the challenges ahead.

Embracing technology is definitely a way to keep their heads above the stormy waters.

Creativity and innovation defined the 23/24 IACDE Summit, ‘Back to the 90s,’ honoring an iconic fashion decade.

Discover how fashion technology trends like virtual twins, AI, and body scanning are transforming the industry, tackling waste, and enhancing...

Dive into the insights from The Interline’s AI Application Era Session where Browzwear leaders discuss the importance of AI in digital product...