4 Effective Strategies for Adopting New 3D Fashion Design Technology

Discover four proven strategies to seamlessly integrate new 3D fashion design technology into your workflow, boosting efficiency and innovation.

June 4, 2023

A paradigm shift is happening in the world of sales samples. Imagine this: Instead of physically creating a plethora of different product variations, sales professionals can now use 3D digital twins, presenting potential customers with a highly accurate, interactive representation of their products. This is not a scene from a sci-fi movie; it’s the reality of today’s sales world, thanks to the innovative world of digital sampling.

The journey of sales professionals has long been complicated, as the traditional sampling process involved a complex choreography of creating, presenting, modifying, and re-presenting physical samples. Now, 3D digital twin technology is turning the tables, offering a unique, immersive customer experience that’s more informed, trustworthy, and sustainable.

The power of 3D digital twins lies in their ability to paint a precise picture of the final product, down to the tiniest details. They bring the product to life, showing how it would look in various real-life scenarios such as motion, stretch, and sizes. Customers can easily compare and contrast different products, giving them the confidence to make decisions swiftly and surely.

In the fast-paced world of fashion, changes are a given. Here’s where digital twins truly shine. Any modification, whether a new fabric selection or a tweak in the design, can be seamlessly integrated into the 3D model. It’s not just a time-saver; it eliminates the need for producing a physical sample for every little change, making it a game-changer in keeping up with ever-evolving trends.

One of the fascinating features of digital twin technology is the ability to access it remotely. This opens up new vistas for sales professionals, who can now conduct virtual presentations or consultations. Imagine showcasing an entire range of styles, sizes, and colorways from the comfort of your office or your home. The boundaries of sales have just expanded.

Digital twins are not just visually stunning but repositories of detailed product information. From size, style, and fabric, to stitching and other specifications, everything a buyer needs to make an informed decision is right at their fingertips. With such comprehensive information, buyers can make decisions quickly and confidently, enhancing the overall purchasing experience.

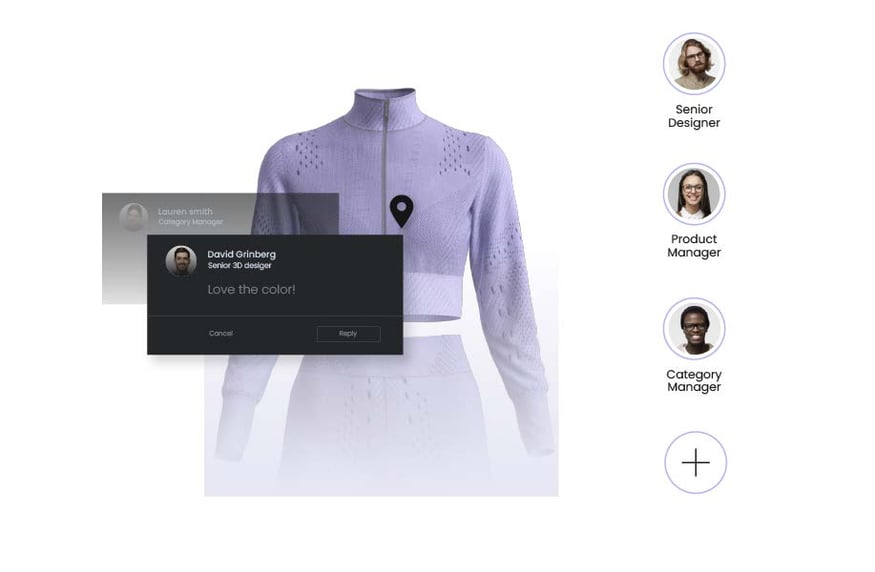

Stylezone takes the power of digital twins a notch higher, providing a virtual space to showcase an entire collection with all its variants. You can now edit assortments in real-time, add comments, and present the garment on various body types, sizes, and stress and tension maps. Whether the meeting is in-person or remote, Stylezone ensures a top-notch presentation.

Beyond efficiency and customer satisfaction, the digitization of the design workflow is also a significant stride toward sustainability. By creating multiple colorways and sizes of a garment in 3D, companies can cut back on natural resources, lower emissions, and reduce textile waste. Brands like Halti have managed to slash their carbon footprint significantly by switching to digital twin technology, making a mark in the eco-friendly evolution of the fashion industry.

Digital twins also significantly speed up the process of getting a product to market. The 3D platform facilitates effortless collaboration, allowing adjustments to be made immediately to the 3D model. This seamless communication reduces the time taken to bring a product to market, a boon for companies in the fast-paced fashion world. Brands like Perry Ellis are already reaping the benefits of integrating 3D technology into their workflow.

3D digital twins are a win-win solution for both businesses and customers. Showcasing a product digitally before its physical production saves significant production and transportation costs and offers a unique opportunity to validate customer requirements. By potentially eliminating the need for physical samples, businesses can enjoy substantial cost savings, contributing to increased profitability.

The accuracy of Browzwear’s digital twins lets you showcase your styles in various colorways and sizes confidently, without creating a physical garment. This leads to quicker market entry, and by reducing the time and costs associated with traditional sample creation, you increase your profitability, sustainability, and efficiency.

3D prototypes are not just a trend but a revolution reshaping the sales sample landscape. By embracing this technology, businesses can stay ahead of the curve, deliver superior customer experiences, boost their profitability, and contribute to a greener future. Welcome to the future of sales, powered by 3D digital twins.

Intrigued by the potential of 3D digital twin technology and ready to propel your business into the future of sales? Browzwear is here to help you transition smoothly into this new era of sales sampling. Contact our team today to learn how our technology can optimize your sales process, enhance customer satisfaction, and contribute to a more sustainable future. Let’s create a new sales narrative together. Contact us today.

Discover four proven strategies to seamlessly integrate new 3D fashion design technology into your workflow, boosting efficiency and innovation.

Explore our guide to 3D fashion design: uncover top software, techniques, and benefits, and see how 3D tech transforms design, production, and...

Learn how to integrate fashion PLM with 3D design software to streamline workflows, boost collaboration, and speed up product development.