4 Effective Strategies for Adopting New 3D Fashion Design Technology

Discover four proven strategies to seamlessly integrate new 3D fashion design technology into your workflow, boosting efficiency and innovation.

October 11, 2024

Traditionally, pattern making was a manual craft. Advanced technologies now allow pattern makers to automate redundant processes, freeing up more time to focus on creativity. Fashion brands and manufacturers are gaining the tools they need to reduce waste and streamline operations, meeting the growing demand for sustainable practices.

In the fashion industry, digital pattern making refers to the process of developing and modifying clothing designs using special software, as opposed to traditional paper methods. With the help of digital technologies, designers and pattern makers can create accurate and scalable garment fit blocks, which can then be used in clothing manufacturing.

Before digital technologies, sewing patterns were created using paper, pens, rules, and French curves. Fashion brands used to make these flat patterns with cardboard for durability and keep them in storage rooms on the rails. Nowadays, this format only exists in couture ateliers or small made-to-order fashion businesses. Medium to large fashion enterprises have transformed this craft into virtual blocks with the help of precision tools offered by 3D fashion design software. The fundamentals of pattern making still remain the same with these technologies, but the precision and automation are impeccable.

Digital pattern making speeds up production processes and contributes to sustainability by increasing efficiency in the fashion design process and minimizing the need for physical samples. The digitalization of this time-honored craft is extremely promising, paving the way for many interesting opportunities in the future of the fashion industry.

The pattern drafting landscape has seen significant advancements in recent years, largely driven by the integration of cutting-edge technologies. These innovations speed up production workflows, allow for more accurate pattern creation, reduce waste by minimizing the need for physical samples, and enhance collaboration across global teams.

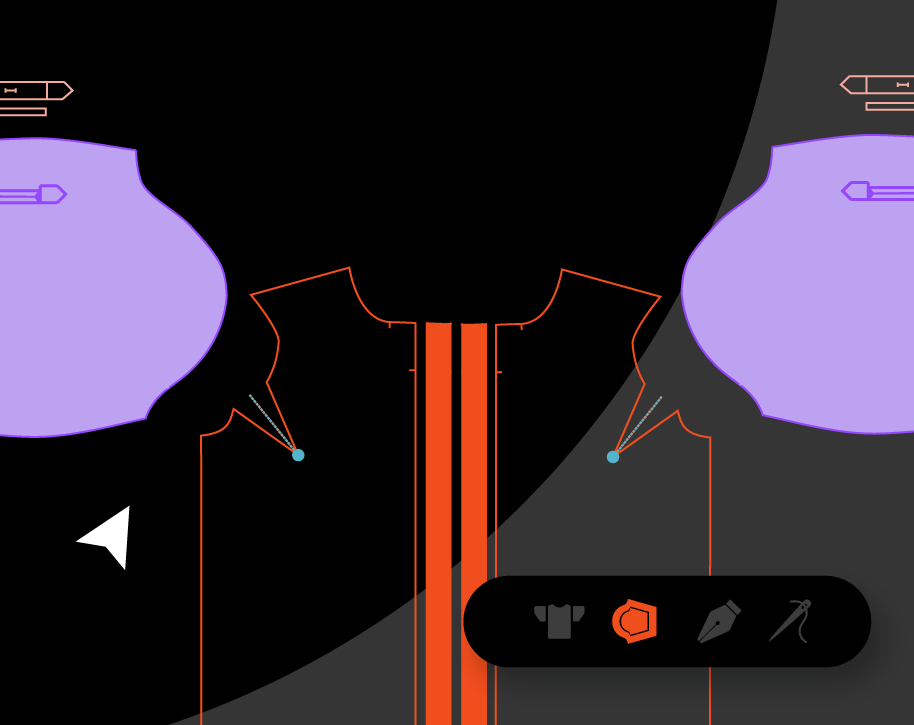

The shift from 2D to 3D pattern making has changed how designers visualize and create clothing. 3D fashion design software allows for real-time modeling of fit, fabric drape, and movement, accurately replicating the finished product before physical samples are generated and, in certain cases, removing the need for physical samples altogether.

Advanced 2D tools within 3D apparel design software help with more precise and true-to-size digital pattern production. In its recent edition, Browzwear introduced new 2D tools to speed up adjustments and approvals, delivering more accurate pattern making without the need for external CAD software.

Designers can use these tools to make faster pattern alterations. The end result is a more efficient pattern making process that lowers errors, shortens development times, and avoids the back-and-forth that is common with traditional pattern approval processes.

The ability to share digital patterns across platforms and locations allows design teams to collaborate effectively, breaking down geographical barriers. With real-time updates, communication becomes more efficient, speeding up the entire product development process, which is especially beneficial in global production chains. Browzwear's 2024.2 edition introduced the evolution of Stylezone, featuring enhanced collaboration tools and new export formats.

The connection between digital pattern making software and PLM (Product Lifecycle Management) systems helps integrate all stages of the product development cycle—from design to manufacturing. This facilitates better tracking, version control, and collaboration across teams.

Rapid advancement in grading and other vital pattern making automation is changing conventional methods that once required manual work. With modern software solutions, tasks such as size grading and pattern adjustments are becoming more efficient and precise.

We believe that digital pattern making will remain a craft in the future. While some say that pattern making will be eliminated or completely automated, the core of pattern making lies in its creative and technical complexities, which robots cannot completely replace. Although some components, such as grading, have already been automated, the creation of unique patterns remains solely in the hands of expert individuals. Their work is now done digitally instead of on paper.

This transition has empowered pattern makers to use technology to improve precision and productivity, but the artistry and expertise required to produce unique designs remain essential. As technology progresses, pattern makers' toolkits will expand, allowing them to explore new creative possibilities and refine their trade. Rather than replacing the pattern maker, these technologies will enhance their job, propelling the craft to new heights by combining human genius and the force of digital innovation.

Digital pattern making dramatically impacts fashion companies and manufacturers, changing product design and production. The technology gives fashion companies more creative freedom, allowing designers to experiment with new concepts and quickly iterate on designs. With rapid prototype capabilities, brands can bring their ideas to life faster, decreasing time-to-market while maintaining a high level of control over the finished product. This increased precision guarantees that clothing is manufactured exactly as designed, from fit to fabric choice.

For manufacturers, digital pattern making provides major operational advantages. Increased precision in pattern replication results in more consistent production outcomes, reducing errors and the need for corrections during manufacturing. This precision, combined with the shorter lead times given by improved digital workflows, helps manufacturers respond more quickly to market demands and handle higher production quantities.

The future potential for automation tools in fashion design, particularly for pattern makers and technical designers, is immense. As 3D technologies continue to evolve, we will see the development of more tools that can automate many of the traditionally time-consuming tasks. These tools will not only make the lives of pattern makers and technical designers easier, but they will also dramatically enhance the efficiency and accuracy of garment production.

In the future, we will see more integrations between various design and production software, fostering a more cohesive and efficient digital ecosystem. This trend is driven by the growing demand for faster, more agile product development cycles and the need to reduce waste and improve sustainability in fashion.

The importance of training future pattern makers in advanced digital tools to meet industry demands will continue to grow. Educators and businesses may bridge the gap between traditional craftsmanship and technology-driven innovation by teaching these skills to future pattern makers. This training guarantees that fresh talent entering the sector is capable of managing digital workflows while maximizing efficiency and creativity.

As technology advances, those who keep ahead of the curve will profit from increased production capacities, more accurate fit, and greater supply chain coordination. By adopting these rising advances, fashion professionals like pattern makers can keep a competitive edge in a rapidly changing market.

Discover four proven strategies to seamlessly integrate new 3D fashion design technology into your workflow, boosting efficiency and innovation.

Discover the best 3D fashion design software, explore features, benefits, and how these tools boost creativity and efficiency.

Discover how 3D fashion design transforms the industry with enhanced sustainability, efficiency, fit accuracy, customization, and innovation.