Trusted Fit: The Key to Reducing Returns and Driving Fashion ROI

Discover how trusted fit reduces returns and drives fashion ROI by cutting costs, speeding time to market, and supporting sustainability goals.

July 1, 2023

"First time right" is a concept that emphasizes the importance of completing a task correctly the first time it is attempted. This approach aims to reduce errors, save time, and minimize the need for revisions or rework, thereby increasing efficiency and productivity. In various industries, especially manufacturing and software development, achieving "first time right" can lead to significant cost savings and quality improvements.

3D fashion design software contributes to the "first time right" principle in the fashion and apparel industry. Why is accuracy so important in achieving the goal of minimal-iteration production? Here are a few main pointers:

3D Prototyping and Visualization: 3D software allows designers to create and visualize garments before they are physically produced. This capability empowers designers and is a critical fashion design tool, enabling them to examine and perfect a garment's fit, style, and functionality without needing physical samples. This approach significantly reduces the time and resources typically spent on sample production.

Accurate and Realistic Simulation: When providing realistic fabric simulation, the viewer understands how a garment will look and behave with different materials. This level of detail, crucial in apparel design software, helps make accurate decisions early in the design process, reducing the likelihood of errors and the need for physical prototyping and revisions.

Streamlined Collaboration: Platforms such as Stylezone facilitate easier collaboration among stakeholders, including designers, pattern makers, and manufacturers, in the garment production process. With features that allow for sharing and commenting on designs within the software, communication is streamlined, and any potential issues can be addressed promptly and correctly the first time.

Integration with Production: It is crucial that the software can generate accurate and detailed production patterns and tech packs, ensuring that the design translated to production is as close to the designer's original vision as possible. This reduces the chances of misinterpretation or errors during manufacturing and highlights the importance of a comprehensive fashion design tool, such as VStitcher, and its wide variety of plugin integrations.

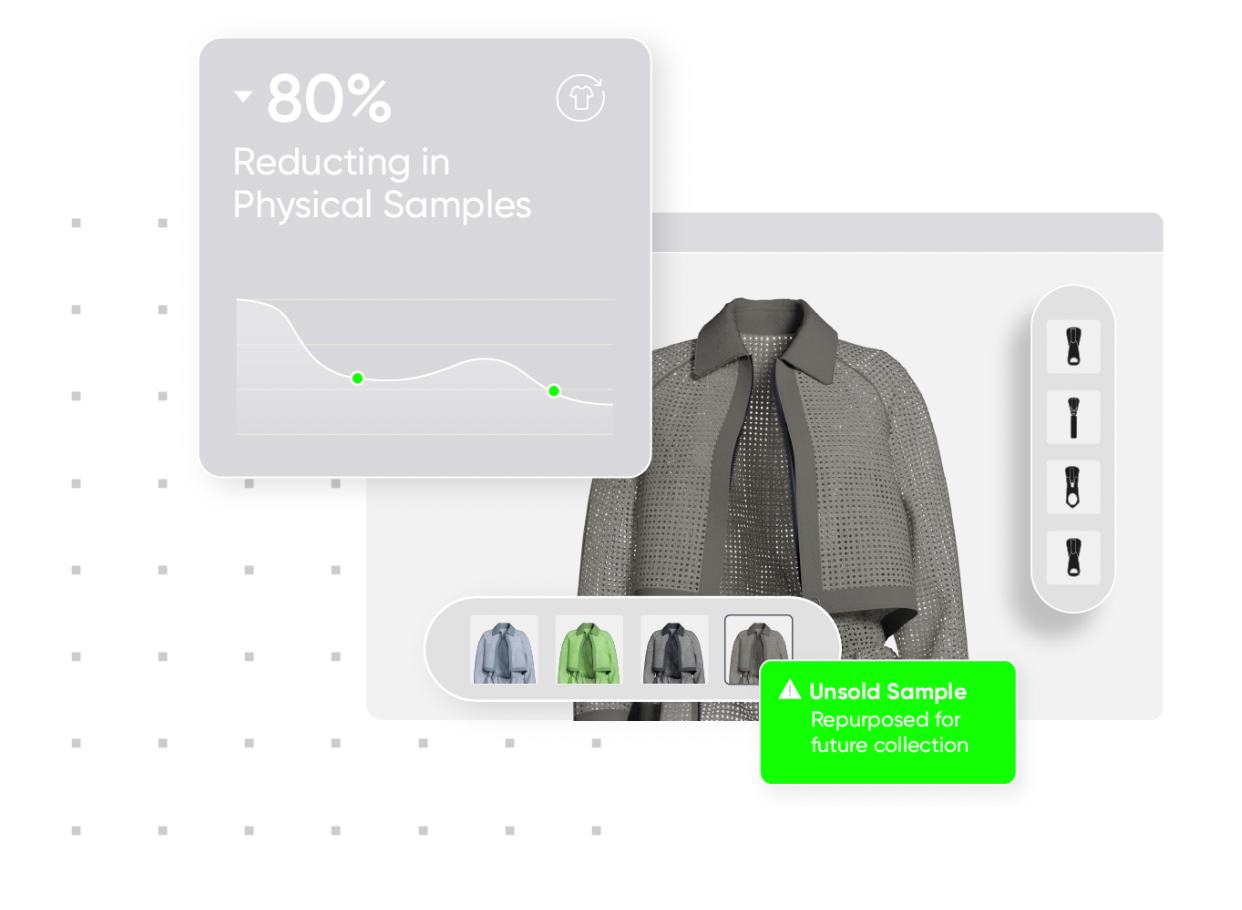

Sustainability: By reducing the need for physical samples, 3D fashion design solutions support sustainable practices within the fashion industry. Less material waste and lower carbon emissions associated with sample shipping contribute to an eco-friendlier production cycle. By reducing the reliance on physical samples, you can significantly minimize fabric waste by up to 80% and salesman samples by 50%. These efficiencies benefit the environment and contribute to cost savings that positively impact your bottom line.

By integrating these features into the garment design and production process, Browzwear helps companies achieve the "first-time-right" objective, leading to cost savings, efficiency improvements, faster time to market, and a more sustainable production model, all underpinned by its sophisticated apparel design software and fashion design tools.

“Before 3D, getting that first sample right often involved a lot of back and forth, which was, of course, time-consuming and costly, especially when shipping samples overseas. By incorporating VStitcher into the early sampling process, we could ensure that the garments' proportions were correct before producing a physical sample, showcase the garment to customers digitally with multiple options, and implement feedback instantly. This would ultimately enable us to reduce the number of physical samples needed and make our customers’ lives easier by providing a spot-on product,”

Discover how trusted fit reduces returns and drives fashion ROI by cutting costs, speeding time to market, and supporting sustainability goals.

Discover how Browzwear’s colorway and graphic automation help fashion teams save hours on material updates, reduce errors, and speed up...

How fashion brands can turn tariff disruption into opportunity with agile workflows, real-time collaboration, and smarter supply chain strategies.