How to Transition from 2D to 3D Design?

Learn how to smoothly transition from 2D to 3D design with essential tools, techniques, and tips to enhance your design workflow effectively.

February 28, 2022

The apparel industry is opening its doors to 3D fashion design and implementing digital workflows across the value chain. As the world grows more environmentally conscious, consumers’ outlook and behavior have shifted toward a more sustainable approach to their shopping habits.

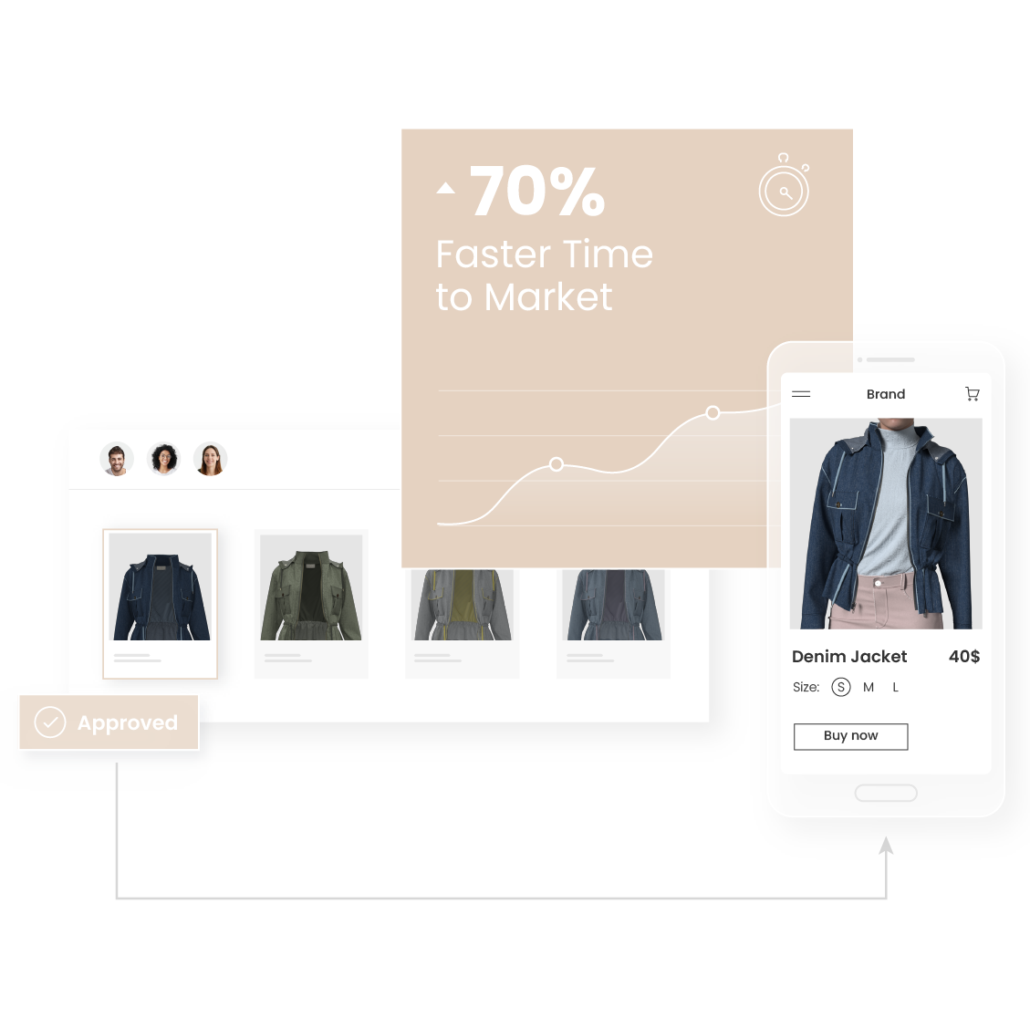

Apparel organizations are now recognizing the potential of 3D fashion design software. It accelerates time-to-market and streamlines workflows while maximizing efficiencies in communication and production.

3D technology is revolutionizing how apparel brands design, produce, and market their products. This modern approach improves creativity, efficiency, and sustainability by making realistic 3D models and simplifying the supply chain. Here's a look at how apparel brands harness the power of 3D technology to stay ahead in a competitive market.

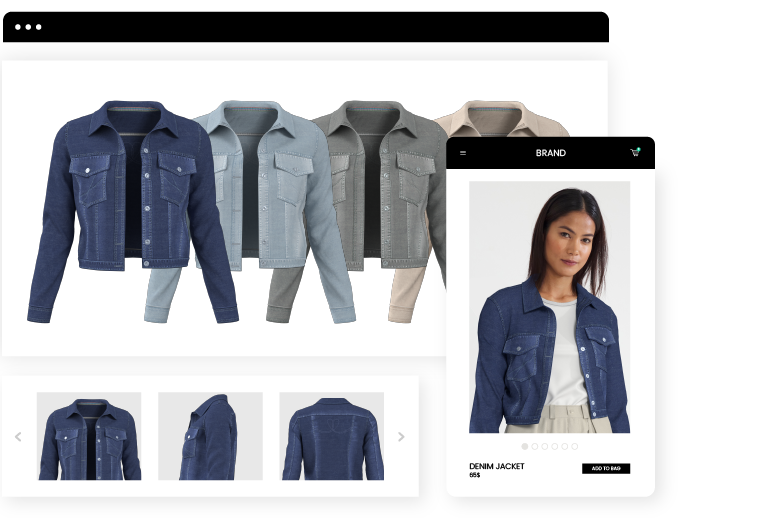

Eliminating the dependency on physical samples helps simplify the design process by enabling designers to digitally draft, edit, and validate styles without sewing a single seam. From a 2D sketch translated into a 3D garment fitted on a human-like avatar, the designer can create patterns and styles directly on the digital garment with the ability to make any adjustments and showcase many variations before taking the design to production.

By creating 3D prototypes, apparel organizations can shorten product development time, make decisions from anywhere worldwide, and simultaneously reduce unnecessary waste.

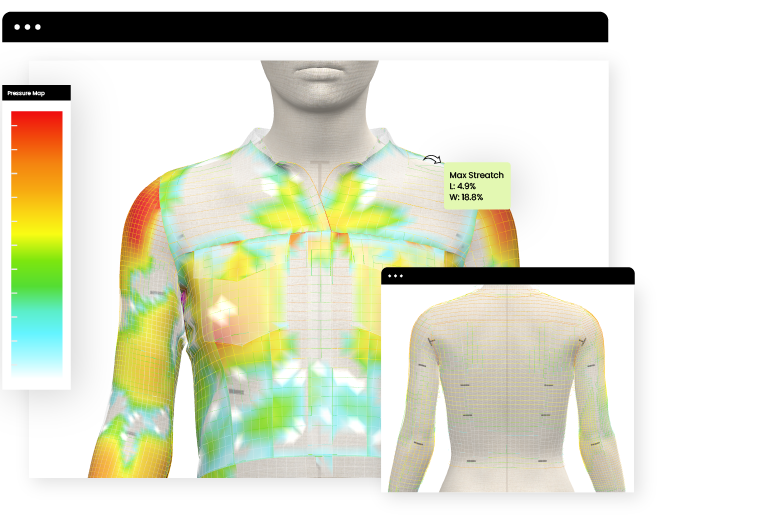

Are you tired of producing multiple physical samples and still getting the same fit inconsistencies? With 3D clothing design software, designers can conduct the fit evaluation process in real-time at an early stage on a digital avatar that can be manipulated according to human body measurements, body types, shapes, and sizes. This lets designers get a true-to-life visual of how the digital garment fits, folds, and drapes when worn on the human body without waiting months to see a physical sample.

Through 3D technology, designers can communicate, review, and approve from wherever they may be in the world and are ultimately connected through a single source of truth.

When it comes to 3D visualization, apparel designers can leverage various features and functions to get the most accurate idea of what the finished piece will resemble.

By analyzing every detail of the garment, including the fabric composition and quality of the garment, 3D visualization helps to improve the manufacturing process by making sure that there is clarity about the requirements and intricate details that make up the garment as well as keeping up with any design changes and evolving ideas.

“ 3D visualization provides a complete product understanding through interaction .”

Apparel designers can spin, zoom, and examine all the intricate details of the garment, make any adjustments if needed, and remove any element of uncertainty about fit. By having these interactive capabilities, apparel organizations are ensuring increased engagement, sales, lower rates of returns, and higher consumer buying confidence.

Designers can showcase their digital samples through many safe and interactive platforms that enable collaboration and validation of garments to design effectively with the input of all stakeholders worldwide and get them involved in the process before any samples are ready.

“ Nowadays, clients are eager to see a glimpse of their project's design even before the work starts .”

Showcasing digital samples lets designers get immediate feedback. It encourages rapid decision-making because stakeholders can collaborate in making edits and adjustments to the garment in real time, reducing time to market.

The 3D design allows for a more streamlined and efficient end-to-end workflow, which results in an accurate pre-production process.

Firstly, there is no pressure on manufacturers to produce physical samples when it comes to the digital design cycle’s manufacturing phase. Secondly, the production of the 3D garment to the physical garment is error-proof as all adjustments have already been made, and “working with digital tools gives manufacturers the advantage of visualizing the end product before being sent to production”. Thirdly, any unsold samples can be altered and repurposed for future collections, resulting in decreased waste.

Undoubtedly, 3D technology is a game-changer in the apparel industry. With the variety of digital tools available, it is in the best interest of apparel organizations to participate in digital transformation, adapt their traditional workflows, and reap all the benefits that 3D offers. This will help them become more agile and responsive to market trends.

Learn how to optimize your business results with 3D

Learn MoreLearn how to smoothly transition from 2D to 3D design with essential tools, techniques, and tips to enhance your design workflow effectively.

Explore our guide to 3D fashion design: uncover top software, techniques, and benefits, and see how 3D tech transforms design, production, and...

Learn how to integrate fashion PLM with 3D design software to streamline workflows, boost collaboration, and speed up product development.