How to Reduce Retail Return Rates

Discover how 3D design technology can reduce high return rates in fashion by improving fit accuracy and enhancing customer satisfaction.

June 3, 2020

The Indie program at Browzwear aims to give talented freelance designers first-hand experience in 3D design. Considering the recent global circumstances, more and more designers are recognizing the need for a remote solution that will allow them to continue their work when physical resources may not be available. As the industry heads in a new direction, digital designers are proving to be the driving force behind this change.

We recently caught up with Keith-Patrick Han, a creative designer who completed our Indie program at the end of 2019 and carried his 3D skills into his future. Regarding fashion design, Keith-Patrick has a broad background covering many different aspects. Whilst studying for his BFA fashion design degree at Pearson's School of Design in New York, he was particularly inspired by the ‘Systems in the Society’ course, which focused on fashion innovation and sustainability, which have become increasingly relevant for the industry and its reputation over the past few years. This course enabled him to look at fashion from a different perspective, working to shape the future of his career.

As Keith-Patrick furthered his education in the field, he geared parts of his curriculum towards 3D design, such as taking classes on 3D modeling that incorporated software programs like Autodesk 360. At this point, he began to dip into several 3D design applications and think about ways that it could be used to save both time and resources and enhance creativity. As part of his thesis, Keith-Patrick came up with his own concept, ‘ assembled.by ’ which proposed the idea of customers self-assembling garments at home via magnetic screws as a means of sustainable fast-fashion, without worker exploitation.

Alongside his work at the Acne Studios denim department and other street style apparel brands, Keith-Patrick was introduced to VStitcher by Browzwear’s 3D expert, Marylina Klenk. This led him to join the Indie program, where he familiarized himself with all of the tools and functions to create his own 3D garments. Working with VStitcher proved to be a user-friendly software for Keith-Patrick, enabling him to go from the patterning to the draping of the garment without the need for a physical sample.

“Essentially, you can do anything that you would like to do”, says Keith Patrick when discussing the capabilities of 3D design. As a result, Keith-Patrick was able to take the concept ‘assembled.by’ and transform it into a reality by utilizing 3D design and rendering.

When discussing the implications of 3D for the future of the industry, Keith-Patrick suggests that although there will naturally be a level of skepticism, “when it comes to embracing digital tools within fashion, it is inevitable that this is where the future is headed” . When transitioning from 2D to working in a 3D environment it can be overwhelming, however, it offers much more room for flexibility throughout the product creation process as it is not confined to a physical location. Changes can be made quickly and easily, and steps can be cut out for a more cost-effective, efficient, and sustainable workflow. He also noted that when designing in 3D, your creative journey is shifted, and it is interesting to see what ideas people come up with.

“ Working with VStitcher as an independent designer, I would say it enables you to visualize ideas immediately without having to invest in physical materials,” says Keith-Patrick.

Keith-Patrick’s knowledge and experience with 3D design have opened up the doors of opportunity, he now pursues his digital design skills at the North Face , which is beginning to look at going down the 3D route. This year’s season creative kick-off, which would have typically been based on physical prototypes, must be carried out digitally for the first time due to the global situation.

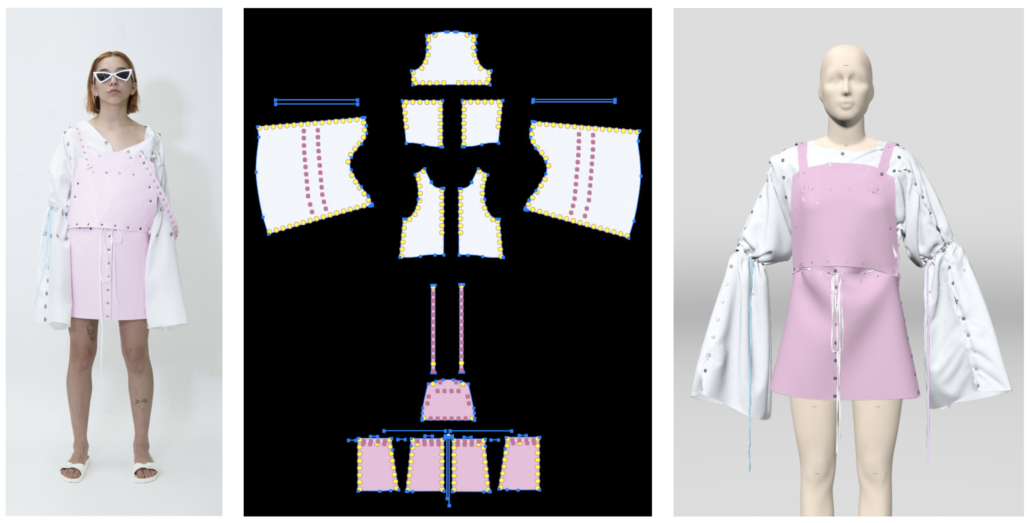

Keith-Patrick’s eye-catching designs have a unique flair that often entails a twist of his much-inspired ’90s style.

“This overall mini skirt is part of a modular self-assembly project made of sustainable PVC. The oversized white top is made of organic cotton. The garment has no seams or stitches, but instead, the garment is assembled by magnetic closures.”

Browzwear’s Indie programTo apply for Browzwear’s Indie program:

Discover how 3D design technology can reduce high return rates in fashion by improving fit accuracy and enhancing customer satisfaction.

Browzwear appoints Greg Hanson as its new CEO. Discover how his leadership will drive innovation and growth in digital fashion product creation.

Box Hill and Browzwear hosted a 3D design event, connecting students, alumni, and industry leaders to explore the future of fashion technology.