bonprix Achieves 30% Time Savings and 100% Digital Fit

Discover the remarkable achievements of bonprix, the renowned global fashion powerhouse, on its digital transformation journey.

No alterations needed for 90% of jeans

Turnaround time reduced to 2 weeks

Enhanced visualization for decision making

Accurate fit validation

“VStitcher provides us with an excellent workflow environment and we are ultimately able to use it as a map to navigate unchartered territory”

Unspun is a leading digital apparel company that produces on-demand, custom-fit jeans dedicated to each and every consumer. Its advanced technology runs on state-of-the-art algorithms to digitally design made-to-measure, perfectly fitting jeans for everyone. Unspun’s design technology works to translate 10-second body scans into digital jeans, eliminating inventory and drastically reducing waste. With a staunch commitment to driving sustainability within the fashion industry, Unspun’s ultimate goal is to reduce global carbon emissions through automated, localized, and intentional denim manufacturing. The company’s innovative technology has been widely adopted by a variety of apparel brands as a smart alternative to traditionally wasteful manufacturing processes. Unspun has been widely acknowledged for its contribution to innovation in recent years, listed in Time Magazine’s Top 100 Best Inventions, PopSci’s Best of What’s New, and more.

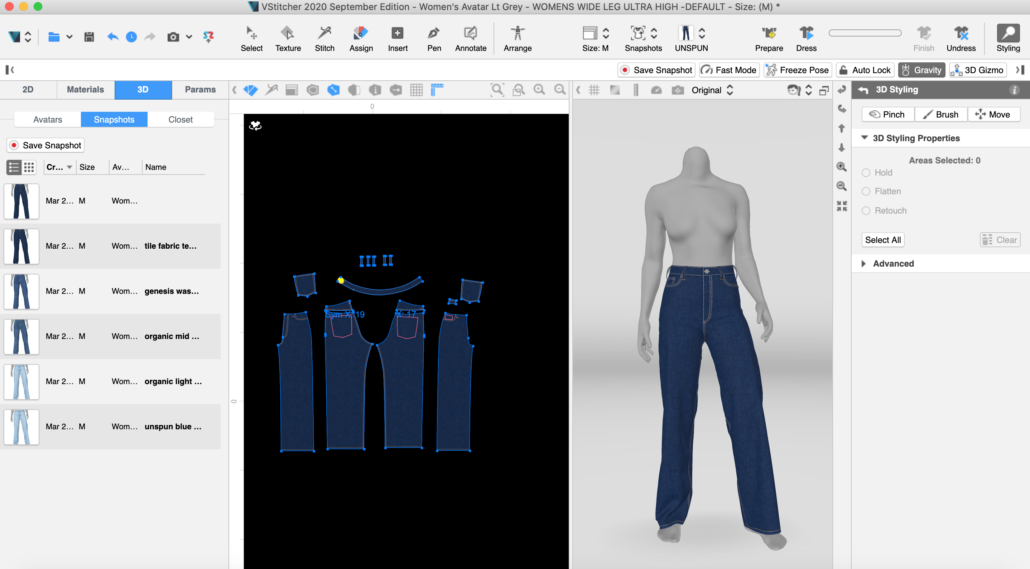

As a rapidly growing startup company, the Unspun team is always on the lookout for new ways to drive innovation and enhance products to achieve the optimal fit for a diverse audience. When attending an event at The Mills in early 2018, the Unspun team came across Browzwear and was eager to learn more about the software and how they could incorporate it into their existing design process. “Although we were already working with 3D rendering systems of our own, we did not yet have the capability to take into account drapes, fabrics, and weight, which are all essential when creating an accurate fit,” says Walden Lam, Co-Founder of Unspun. “Once I began my onboarding process to Browzwear’s VStitcher and saw that it offered features including heat and pressure maps, and allowed you to contextualize fabrics, it immediately clicked that this should be a part of our routine when developing jeans on-demand,” adds Walden.

What particularly attracted the team at Unspun to Browzwear’s software was that it would enable them to upgrade their visualization capabilities and fit validation, and ensure consistent quality control. With their new tool, they immediately got to work and began incorporating VStitcher as an integral part of the jeans customization process. “Since introducing Browzwear into our design workflow, we essentially render every pair of jeans per customer, which allows us to accurately visualize and analyze the exact fit of the jeans on all different body types,” says Walden. In fact, some of Unspun’s customers have begun to request 3D visuals throughout the entire customization process to compare and contrast different cuts, such as skinny versus tapered, when deciding what is best for them. For this part of the process, Unspun offers a 3D body scan, which can be transformed into a personalized avatar to place the 3D styles on and observe how the fabric fits on the body.

“As we continue to perfect the integration of our 3D scanning system and VStitcher, we have now been able to hit a rate of 90% with no alterations needed and with turnaround time being as little as two weeks,”

To achieve the most accurate outcome, pre-washed fabrics are sent to Unspun’s Hong Kong team for digitization, and that way, any twisting or shrinkage that typically occurs with denim is already accounted for throughout the fit process. “Since utilizing Browzwear’s software for the fit process, we have found the accuracy to be of an extremely high level and a realistic representation of how the different styles and cuts of jeans would look when worn on different shapes and sizes,” says Walden. As each customer is provided with 3D visualization and referred to as a styling guide, any adjustments can be made long before the physical version is produced. “VStitcher provides us with an excellent workflow environment and we are ultimately able to use it as a map to navigate unchartered territory,” notes Walden, “It allows you to be a perfectionist with the fit of each pair of jeans, and magnifies issues that may have occurred further down the line, enabling you to adjust them accordingly, early on in the process.”

“Since utilizing Browzwear’s software for the fit process, we have found the accuracy to be of an extremely high level and a realistic representation of how the different styles and cuts of jeans would look when worn on different shapes and sizes,”

Now, as a fundamental part of the process, Unspun’s raw 3D scan is pulled into VStitcher, and the team can utilize the 3D environment to ensure that the fabrics are accurately placed on the body. In essence, as opposed to traditional denim shopping, Unspun’s customers have the confidence to purchase a customized fit, rather than trying on multiple garments or struggling to find an in-between size. “As we continue to perfect the integration of our 3D scanning system and VStitcher, we have now been able to hit a rate of 90% with no alterations needed, and with turnaround time being as little as two weeks,” says Walden.

After seeing the pandemic’s impact on retail stores, leaving brands flooded with stock, the denim industry has seen an even greater need for on-demand production and 3D visualization. Therefore, the team at Unspun is looking beyond the horizon to bring even further customization and real-time scanning to the fashion industry in the near future.

Discover the remarkable achievements of bonprix, the renowned global fashion powerhouse, on its digital transformation journey.

Discover how Perry Ellis uses Browzwear’s 3D technology to enhance design efficiency, cut costs, and innovate with a smart-to-market approach.

Tendam leverages Browzwear's 3D tech to boost speed-to-market, enhance creativity, and reduce waste across its fashion brands.